Address: Building 7, Xianzhuang Industrial Park, No. 1, Pingan 2nd Road, Xianzhuang Industrial Park, Lirendong, Nancun Town, Panyu District, Guangzhou

Service Hotline:020-39211688

Address: Building 7, Xianzhuang Industrial Park, No. 1, Pingan 2nd Road, Xianzhuang Industrial Park, Lirendong, Nancun Town, Panyu District, Guangzhou

(Summary description)Recently, the sewage treatment plant in the relocation project of Tianjin Dongjiao Sewage Treatment Plant and Reclaimed Water Plant was officially put into commercial operation. The reclaimed water plant has entered the commissioning stage and is expected to be put into use in September.

(Summary description)Recently, the sewage treatment plant in the relocation project of Tianjin Dongjiao Sewage Treatment Plant and Reclaimed Water Plant was officially put into commercial operation. The reclaimed water plant has entered the commissioning stage and is expected to be put into use in September.

Recently, the sewage treatment plant in the relocation project of Tianjin Dongjiao Sewage Treatment Plant and Reclaimed Water Plant was officially put into commercial operation. The reclaimed water plant has entered the commissioning stage and is expected to be put into use in September.

By then, this "super project" covering an area of 420,000 square meters will have a daily sewage treatment capacity of 600,000 tons, and a daily treatment capacity of 100,000 tons of reclaimed water , benefiting 4 administrative regions and more than 1.95 million residents. It will take over Tianjin City. One-fifth of the sewage purification task will help improve the overall water environment quality in the Beijing-Tianjin-Hebei region.

The new site of Dongjiao Sewage Treatment Plant is located within the angle range of the northwest side of the Jingjintang Expressway and the Outer Ring Line Adjustment Line. The total land area of the project is 422,300 square meters, and the estimated total investment is 3.699 billion yuan. After completion, the daily sewage treatment scale will be 600,000. The daily treatment scale of recycled water is 100,000 tons, and the total service area is 14,370 hectares, benefiting Hongqiao District, Hebei District, Hedong District, and Dongli District, serving a population of approximately 1.95 million.

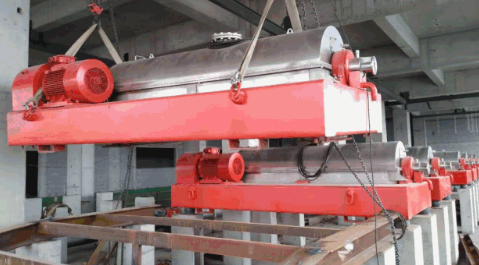

China Construction Installation No. 1 participated in the construction of biological tanks, secondary sedimentation tanks, ozone contact tanks, sludge treatment workshops, ultraviolet disinfection channels and all monomer process equipment and electrical engineering in the reclaimed water area of the sewage treatment plant.

How big is the largest semi-underground sewage treatment plant in Asia? The builders answered: The Dongjiao Sewage Treatment Plant has a huge volume, equivalent to 60 football fields ; 42,000 pipe piles, with a cumulative length of more than 600,000 meters, and a height equivalent to 68 Mount Everest; 1.47 million cubic meters The unearthed volume is equivalent to 1.6 water cubes; 90,000 tons of steel bars have been used in total, which is equivalent to the total steel consumption of 2.5 National Stadium Bird's Nest...

Looking around, like green grasses, green corridors, unique pavilions, and blooming flowers, who would have thought that there is a huge sewage treatment plant at your feet? Tian Jin eastern outskirts of the sewage treatment plant and recycled water plant relocation project only had 24 underground pit the size of a standard football field , in order not to affect the park landscape, semi-underground construction project design, including the aerial parts needed for the production management activities Space and an ecological garden, all sewage treatment equipment are underground.

"Just like desktop computers, display screens and other accessories are on the ground, and the host is buried underground. The main equipment is sunk underground , which solves the problems of pollution and noise generated in the sewage treatment process, and has minimal impact on residents and the environment. " Manager Ren Zhanju said. The above-ground park also incorporates the concept of "sponge city" construction, using grass-planting ditches, permeable paving, rain gardens, etc. The plant is integrated into the entire ecological park through the design of gentle slope and vertical greening.

How does the sewage gathered from the sewage pipe network complete this journey of transformation from "turbid" to "clean"? The project team adopted the wastewater treatment process of "improved multi-stage AO + high-efficiency sedimentation tank + deep bed filter + ozone oxidation + ultraviolet disinfection" .

The sewage is pre-treated for slag discharge and initial precipitation, and then enters the high-efficiency sedimentation tank and deep-bed filter to remove suspended particles after being decomposed by microorganisms in the biological tank. After deodorization and ultraviolet disinfection by the ozone system, the effluent quality can reach Tianjin City. Local discharge A standard, part of the effluent can be directly discharged to the park as landscape and wetland water.

The reclaimed water treatment adopts the "ultrafiltration + reverse osmosis" treatment process , and the effluent can be reused in thermal power plants, chemical plants, and toilets, realizing water resources circulation.

In the 14-meter-deep underground of the ecological park, the sewage pipeline network assumes the important task of "one-stop sewage transfer". Traditional water plant pools are connected by buried pipelines on the surface, which can be transported and constructed by crane.

The project department enters the construction site after the civil structure is sealed. All large pipes need to enter the box from the two reserved lifting holes. Due to the small construction space and most of the pipe corridors are distributed at the bottom of the closed box, the heaviest single pipe can reach Over 10 tons, cranes and large trailers cannot be used during transportation and construction. How to quickly transport the pipeline to the underground for installation has become a "blocker" in the project construction.

The project team has innovatively developed a confined space plane transportation technology and built a "subway" for pipeline transportation. The construction personnel lay the transportation track in the box, and use the track trolley to transport the pipeline to the lifting hole position in the order of the welding joint layout, and then use the self-made gantry crane to lower the pipeline into the pipe gallery and transport it to the construction site for installation .

The successful application of this technology guarantees the installation of 10,000 meters of pipelines, avoids damage to the anti-corrosion layer of the pipeline during transportation, and finally completes the node goal on schedule.

Soldiers are not many but are fine, and they will not be courageous but plan. At the beginning of the project, there were only 6 managers who were responsible for nearly 100,000 square meters of equipment, pipelines and electrical installation and commissioning. The construction area is wide, and most of them are underground space operations. The project department implements a regional responsibility system, and each manager claims an area. The "district chief" is responsible for the material procurement, material acceptance and post-system commissioning of the scope.

During the Spring Festival, in order to achieve the official live and water commissioning goals, the project team led more than 120 workers to conduct power transmission inspections and pipeline installation inspections in the sludge treatment workshop and 7 10kv high-voltage power distribution rooms, implementing the "two shifts" mode , The high-voltage power distribution room testing and debugging work, which originally took 15 days to complete, was compressed to 3 days to complete.

(Source: CCTV.com Original title: Officially put into operation! Demystifying Asia's largest semi-underground sewage treatment plant)

Scan the QR code to read on your phone

Phone:020-39211688 18008627251

Post Code:511442

Fax:020-34698181

Email:sales@uvc.com.cn/info@uvc.com.cn

Address: Building 7, Xianzhuang Industrial Park, No. 1, Pingan 2nd Road, Xianzhuang Industrial Park, Lirendong, Nancun Town, Panyu District, Guangzhou

Disclaimer | Website construction: www.300.cn